NAC5023-Hxx

- NAC5021-Hxx

- NAC5022-Hxx

- NAC5023-Hxx

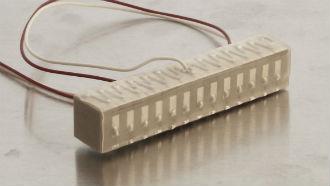

Noliac damage tolerant actuator stack NAC5023-Hxx (height in mm – Hxx) is a multilayer actuator that can be stacked to match your requirements. The fuse technology of the damage tolerant stack fuses out any damaged ceramic element and the remaining ceramic elements continue to operate. This makes the damage tolerant stack an effective way to ensure high reliability for critical applications. The damage tolerant stack provides a stroke up to 244.2 µm and blocking force up to 9450 N depending on the height of the stack.

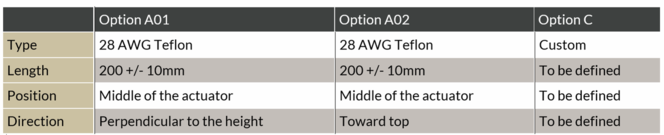

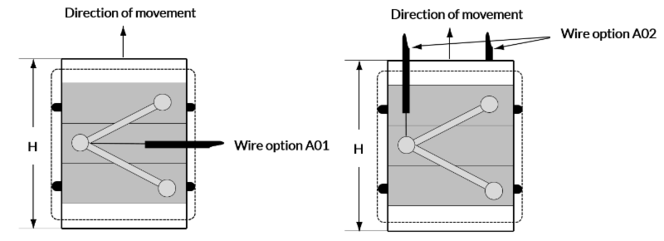

Stack options

Mounting

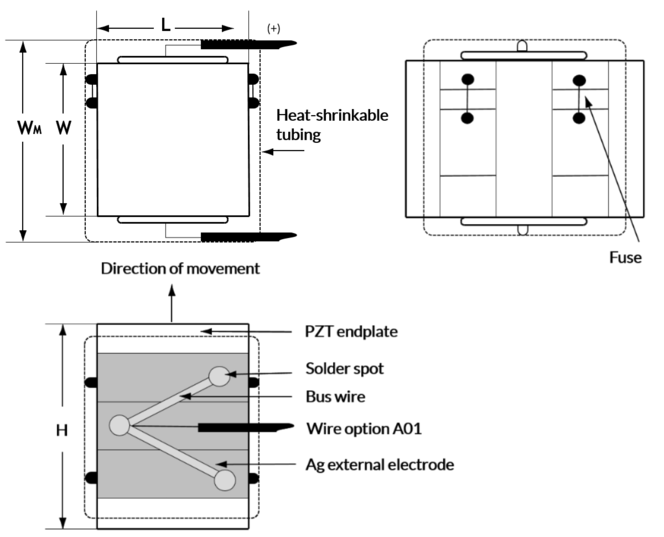

The stacks have ground top and bottom insulating ceramic end-plates in order to obtain flat and parallel surfaces for mounting. The stacks may be mounted either by mechanical clamping or gluing.

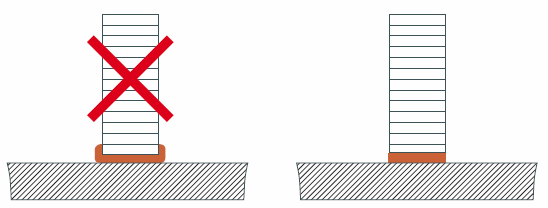

If glued, it is important to ensure a very thin glue line between the actuator and the substrate. It is recommended that a pressure, e.g. 2-5 MPa, is applied during the curing process.

During manufacturing or handling, minor chips on the end-plates can appear. Minor chips cannot be avoided, but such chips do not affect performance.

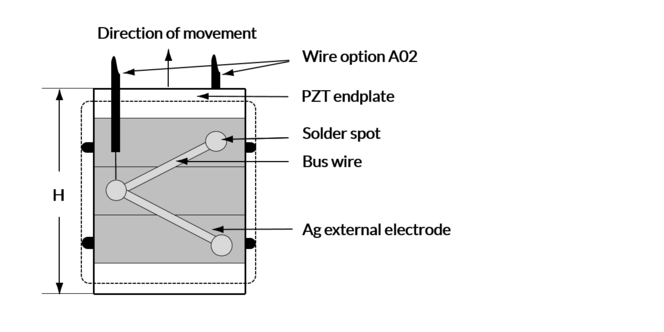

Electrical connection

The positive electrode is indicated by the red wire.

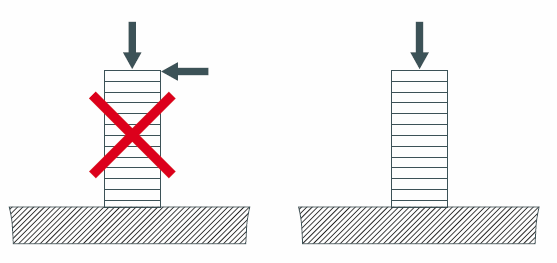

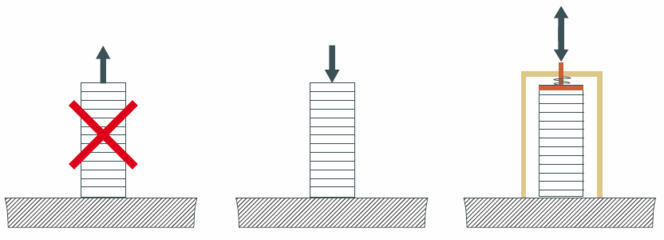

The actuators may only be stressed axially. Tilting and shearing forces must be avoided.

The actuators without preload are sensitive to pulling forces. It is recommended to apply a pre-load in order to optimize the performances of the actuators.

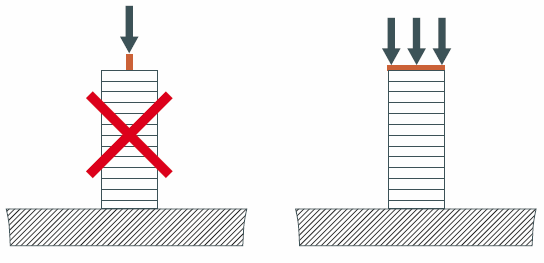

The force must be applied on the full surface of the actuator in order to assure a good load distribution.

Epoxy glues are well suited for gluing piezoceramics.

The Noliac fuse stack is delivered with wires. Therefore, when you order a fuse stack from Noliac, you have to select one of our wire options below. You should consider these parameters, when you select a wire for connection:

- Operation voltage

- Intensity of current

- Operating temperature

- Environment

We recommend Teflon wires

Teflon wires can stand temperatures above 200 °C, whereas PVC wires only resist temperatures up to 80 °C. In tough operating conditions or in vacuum, it is recommended always to use Teflon isolated wires to guarantee the proper performances of PZT elements.

Wire thickness (AWG)

The wire thickness is determined by the current that has to be transmitted to and from the PZT element. The required current is determined by the capacitance of the PZT element, the maximum driving frequency and the maximum voltage Up-p.