NAC6025-Hxx

- NAC6024-Hxx

- NAC6025-Hxx

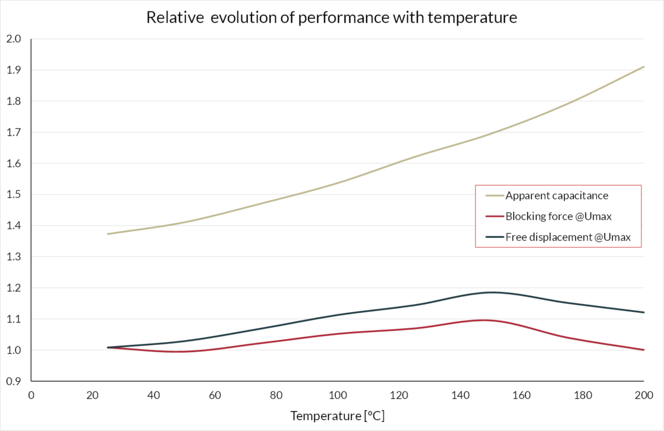

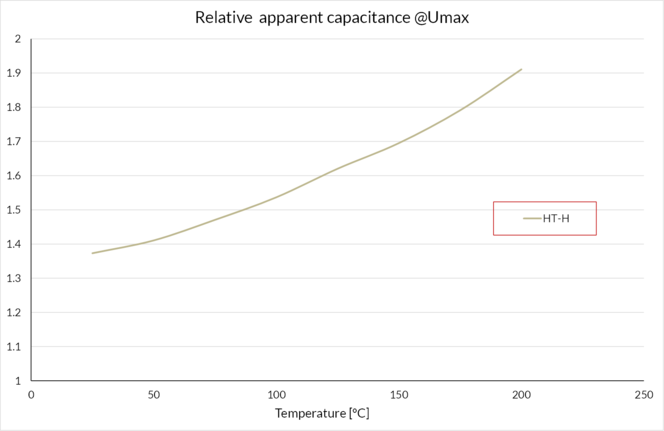

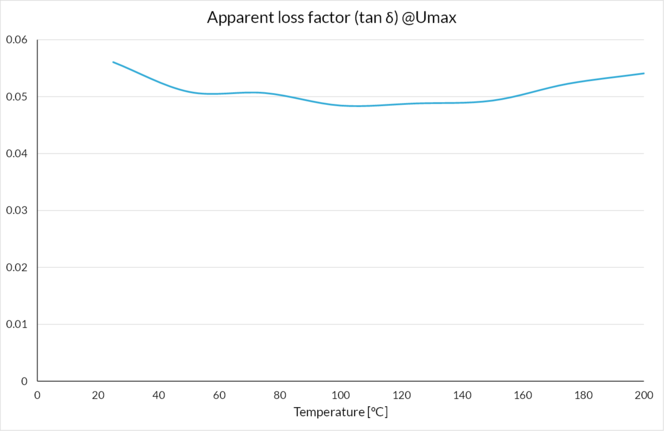

Noliac high temperature plate stack actuator NAC6025-Hxx (height in mm – Hxx) is designed to perform at high temperature and high frequency. The maximum operating temperature is 200 °C, and combined with a high frequency operation, this is a perfect match for applications, where high temperature and high frequency is a challenge. The actuator can be stacked to match your specific requirements. The standard range of NAC6025-Hxx is produced in a height between 4-50 mm at an unloaded resonance frequency up to 35 kHz depending of the height of the stack.

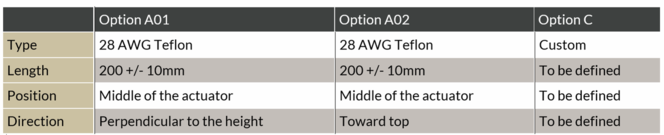

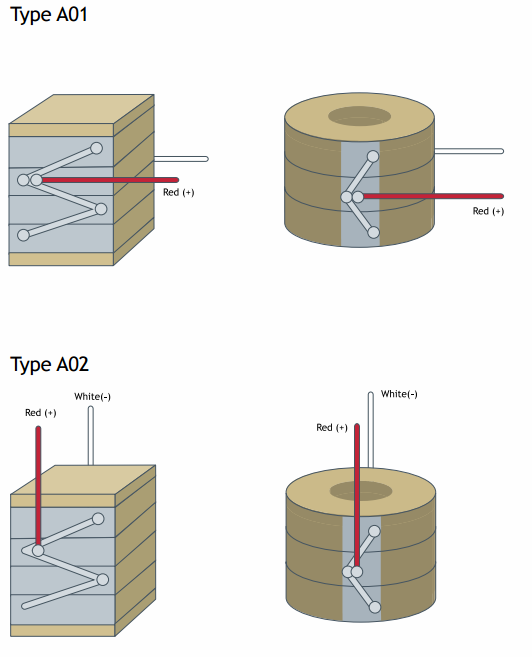

Stack options

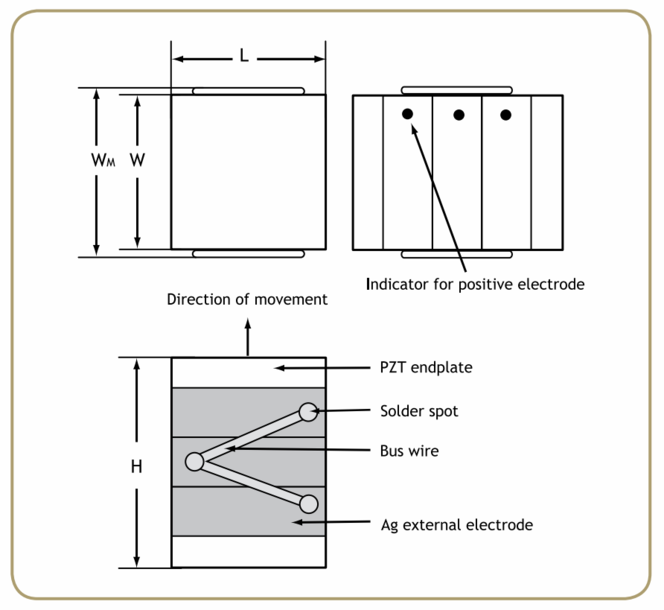

Here you can find a drawing of the outline of the high temperature stacks and a number of graphs showing different aspects of the performance at high temperature.

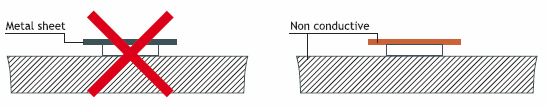

Mounting

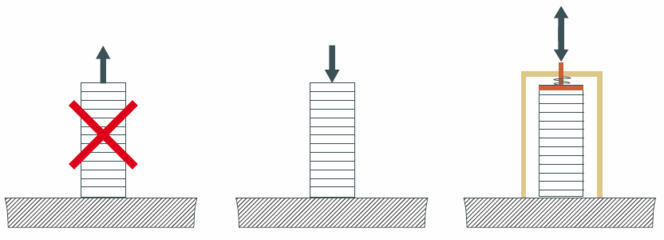

High temperature actuators must be mounted under preload by mechanical clamping.

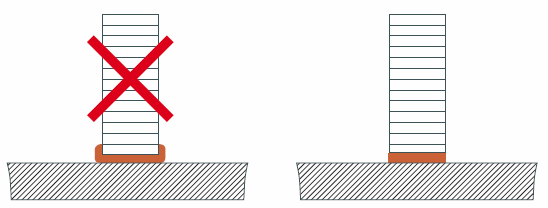

If glued, it is important to ensure a very thin glue line between the actuator and the substrate. It is recommended that a pressure, e.g. 2-5 MPa, is applied during the curing process.

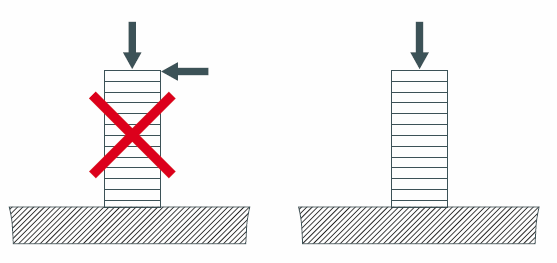

To avoid significant loss of performance, the mounting of the actuators should avoid mechanical clamping and/or gluing on the sides of the actuator.

During manufacturing or handling, minor chips on the end-plates can appear. Minor chips cannot be avoided, but such chips do not affect performance.

Electrical connection

External electrodes

The external electrodes are screen printed silver as standard.

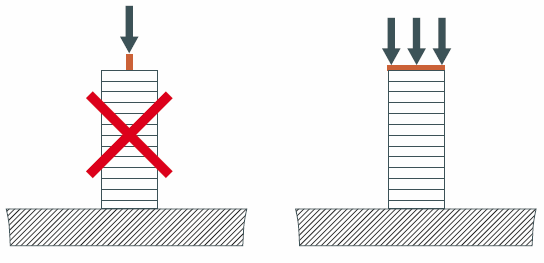

The actuators may only be stressed axially. Tilting and shearing forces must be avoided.

The purpose of the epoxy used in HT stacks is to hold the components between shipment and assembly. At high temperature, the epoxy cannot ensure sufficient adhesion, so it is necessary to apply a preload to maintain the integrity of the stack. A compressive preload of 5MPa is recommended, although higher values can be applied if the application requires it.

The force must be applied on the full surface of the actuator in order to assure a good load distribution.

Epoxy glues are well suited for gluing piezoceramics.

When you order actuators from Noliac, you can have wires fitted to save time and money. However, you should consider these parameters, when you select a wire for connection:

- Operation voltage

- Intensity of current

- Environment for example vacuum

We recommend Teflon wires

Teflon wires can stand temperatures above 200 ºC, whereas PVC wires only resist temperatures up to 80 ºC. High-temperature stacks are fitted with Teflon isolated wire to guarantee the proper performance of PZT-elements. For Ultra-High Vacuum (UHV) operations, high-temperature stacks are fitted with Kapton isolated wires.

Wire thickness (AWG)

The wire thickness (AWG) is determined by the current that has to be transmitted to and from the PZT-element. The required current is determined by the capacitance of the PZT-element, the maximum driving frequency and the maximum voltage Up-p.