CMBR07

- CMBR02

- CMBR03

- CMBR04

- CMBR05

- CMBR07

- CMBR08

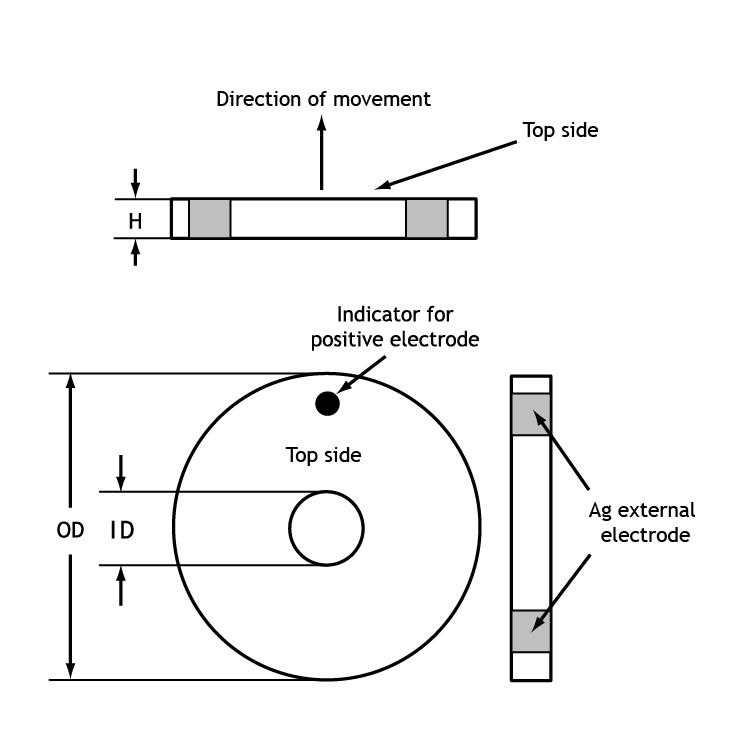

The ring benders are manufactured with ceramic layer thickness down to 20µm as standard to facilitate very low operating voltage for full performance of the piezo material. CMBR07 measures 40x8x0.7 mm. The bender provides a free stroke of ±185 µm and a blocking force of 13 N.

Mounting

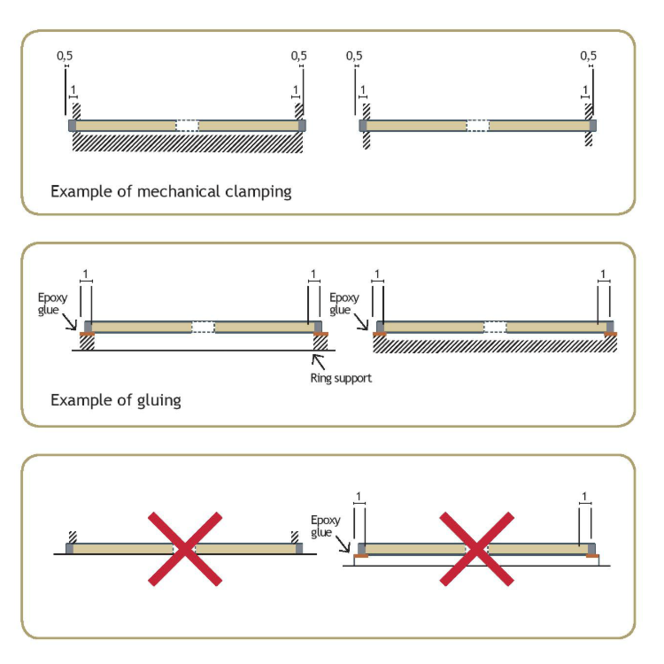

Bending ring actuators may be mounted either by mechanical clamping or gluing.

Mechanical clamping

A mechanical clamping should be done with moderate force, as low as possible to avoid unwanted clamping and thus reduce the maximum stroke.

Gluing

Epoxy glues are well suited for gluing piezoceramics and several alternatives exists. Please contact us, if you need support on selecting the appropriate glue for your application.

Important remark:

Mounting of bending ring actuators at their outer diameters needs some flexibility at the contact line to avoid unwanted clamping that will reduce the benders efficiency. Therefore, mechanical clamping should be done with moderate forces and if the ring is glued, a flexible epoxy should be used.

Control instructions

Bending ring actuators can be controlled by:

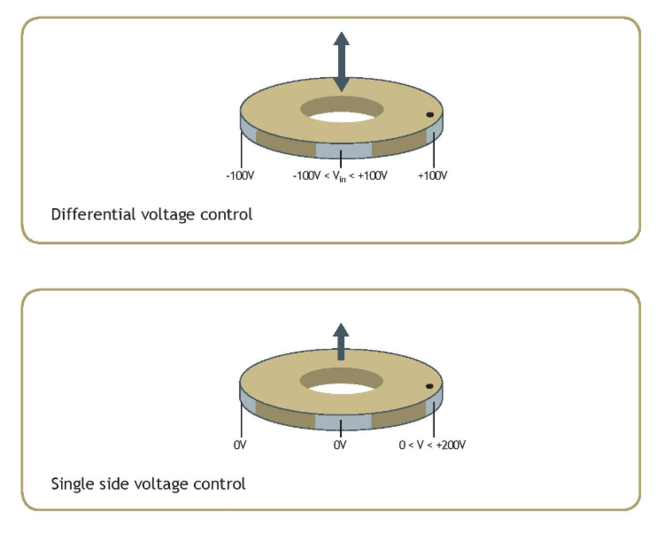

Differential voltage control

In this mode the bending can be controlled both upwards and downwards. Apply +100 V to the positive electrode (indicated by the black dot), -100 V to the negative electrode and a voltage Vin to the middle electrode such as -100V<Vin<100 V.

If 0 V<Vin<100 V, the ring will bend down with the black spot facing up.

If -100 V<Vin<0 V, the ring will bend up with the black spot facing up.

Single side voltage control

In this mode, the bending can be controlled for one side only, i.e. bending up with the black dot facing up. Apply 0 V to the negative and middle electrode, and up to 200 V to the positive electrode.

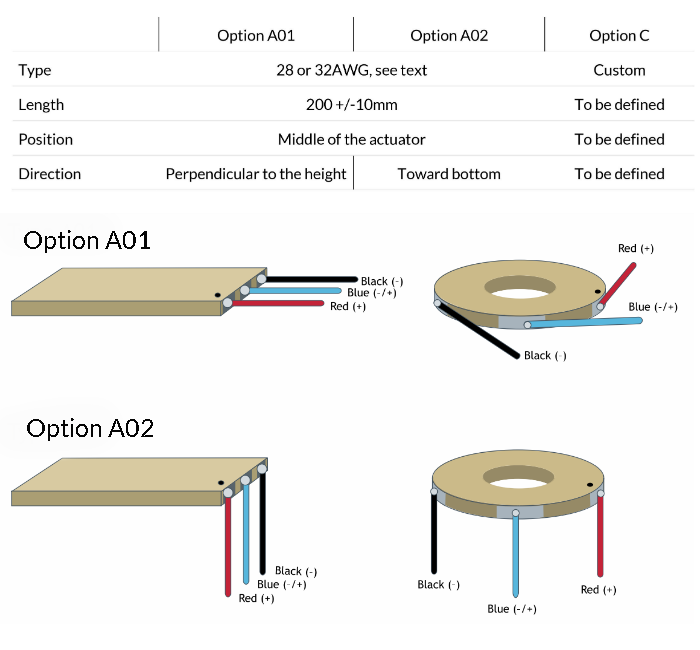

Noliac attaches these wires as standard to our plate and ring benders:

- 28 AWG MIL-W-16878/4, 7 strands wires to products with a thickness equal to or thicker than 1.2 mm.

- 32 AWG MIL-W-16878/6, 7 strands wire wrap to products thinner than 1.2 mm and thicker than 0.5 mm.

On products thinner than 0.5 mm we recommend the customer to glue the wire onto the terminals using conductive glue e.g. EPO-TEK®H27D.

We solder red wires to the positive electrode, black to the negative and blue to the control terminal on benders.