Although there are several types of piezoelectric ceramic materials available today, most can be placed into one of two general categories: “Hard” materials and “soft” materials. The perovskite structure is very tolerant to element substitution (doping) – therefore the terms “hard doped” and “soft doped” are used. Even small amounts of a dopant (~1%) may cause huge changes in the properties of a material.

These are the topics covered by this page:

Characteristics of hard doped piezoceramic material

Hard materials are suitable for dynamic/on-resonance applications, where the high mechanical quality factor determines the amplification of the deflection at resonance. Hard materials can withstand high level of electrical excitation and mechanical stress, and are not easy poled or depoled except at elevated temperature. However, this stability is accompanied by relatively low piezoelectric constants (i.e. low strain). If intending to use piezoelectric components in high power applications for instance, e.g. for ultrasonic cleaning, it is strongly recommended to select products based on a hard-doped piezoceramic material, which has roughly a factor 10 lower losses than “soft” materials and will therefore heat-up less.

Characteristics of soft doped piezoceramic material

Soft ceramics feature high sensitivity and permittivity and are well suited for static or semi static applications, where large deflections are required. They produce larger displacements because their piezoelectric constants are higher. However, when operated in dynamic mode at high field such soft piezoceramic material types suffer from high dielectric losses and high dissipation factors, which may lead to overheating over an extended period of operation.

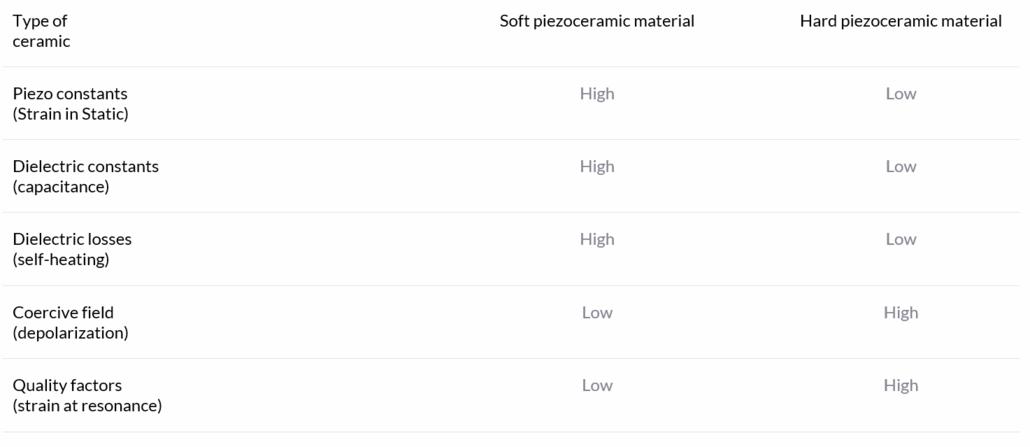

Below you can see a comparison of the characteristics of the hard and soft doped piezoceramic material.

Sign up for our webinars

Our free 1.5 hour webinars follow the same structure as our tutorials.

A piezo partner - what do we mean by that

We give you a competitive advantage by using our extensive knowledge to customize and optimize your piezo products. Thus, we will be your long-term piezo partner. Send your request today.

Search tool

- Plate actuators

- Plate stacks

- Ring actuators

- Ring stacks

- Plate benders

- Ring benders

- Shear plate actuators

- Shear stacks

- 2D actuators

- High temperature stacks

- Damage tolerant stacks

- NCE51

- NCE51F

- NCE46

- NCE57

- NCE40

- NCE41

- NCE55

- NCE56

- NCE59

- NCE81

- 0,00

- AA

- Material

- Type

- 0.00