The electric and piezoelectric properties are affected by temperature variations. Each piezoelectric material is affected differently by temperature changes, according to the method of manufacture and chemical composition of the material.

These are the topics covered by this page:

Maximum temperature

Piezoelectric materials should be used well below their Curie temperature for the poling to be stable. Any conditions that raise the temperature close to the Curie temperature will cause the piezoelectric material to become partially or completely depoled and severely degrade performance. For applications that require operation at elevated temperature a material with a sufficiently high Curie temperature must be chosen. Maximum recommended operating temperatures are specified for each product. It is important to monitor temperature, in particular for dynamic applications where self-heating can occur.

Minimum temperature

Our multilayer products can be used at cryogenic temperatures and have been demonstrated down to 4mK. For these applications a specific preparation (wires, adhesive etc.) is required.

The mechanical and electrical properties of piezoelectric ceramic are greatly reduced at cryogenic temperatures. When piezoelectric actuators are cooled down to cryogenic temperatures, the piezoelectric ceramic behaves like a very hard piezoelectric material featuring:

- Strong reduction of electrical capacitance

- Reduction of loss factor

- Reduced strain coefficients d33 and d31

- Strong increase of the coercive field.

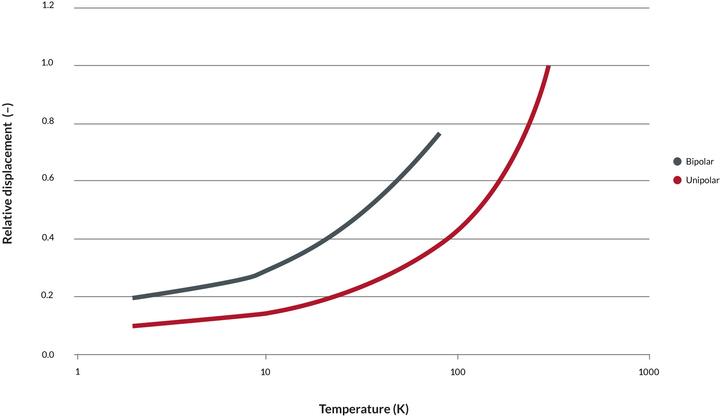

The last point means, that at low temperatures a piezoelectric actuator becomes extremely stable against electrical depoling. Therefore, a much wider bipolar operation compared to room temperature is possible. Thereby, the loss in stroke for low temperature can be partially compensated for.

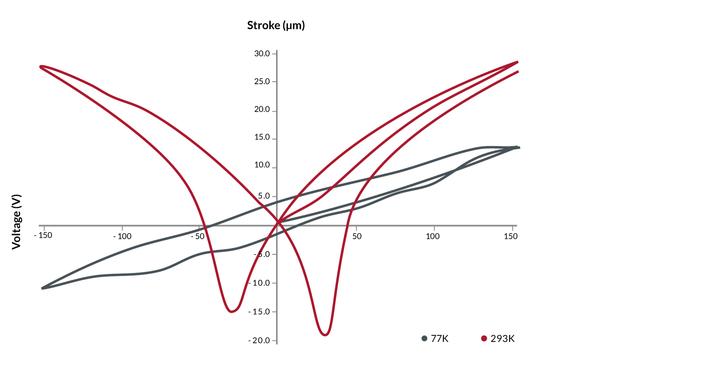

Below is an example of cryogenic measurements at two different temperatures showing the relationship between stroke and voltage. As it can be seen, the strain at 77 K is approximately reduced to half the value at room temperature. Due to the strong increase of the coercive field, it can also be observed that the actuator exhibits a fairly linear voltage-displacement characteristic at negative voltage. The piezoelectric actuator becomes extremely stable against electrical depoling and the loss in stroke at low temperature can be partially compensated by using a wide bipolar operation.

A more problematic parameter is the thermal expansion coefficient for ceramics, important to consider when designing devices where piezoelectric actuators will be part of a composite structure and where the other elements of constructions are e.g metals. The thermal expansion coefficient for ceramics is similar to many ceramics and glasses and is typically in the range of 10-5 to 10-6/°C. A major difference with common materials is that the thermal expansion coefficient is anisotropic with respect to the poling direction.

Sign up for our webinars

Our free 1.5 hour webinars follow the same structure as our tutorials.

A piezo partner - what do we mean by that

We give you a competitive advantage by using our extensive knowledge to customize and optimize your piezo products. Thus, we will be your long-term piezo partner. Send your request today.

Search tool

- Plate actuators

- Plate stacks

- Ring actuators

- Ring stacks

- Plate benders

- Ring benders

- Shear plate actuators

- Shear stacks

- 2D actuators

- High temperature stacks

- Damage tolerant stacks

- NCE51

- NCE51F

- NCE46

- NCE57

- NCE40

- NCE41

- NCE55

- NCE56

- NCE59

- NCE81

- 0,00

- AA

- Material

- Type

- 0.00